Chemicals in the automotive industry

Certified under IATF: 16949

In 2021, we have achieved the highest certification for our auto products, having adapted all our automotive materials production centers under IATF 16949:2016, the international standard for quality management systems in the automotive industry.

It is the most demanding standard for quality management systems in the automotive sector on an international level, and one of the essential requirements that car manufacturers require of their suppliers.

We have a wide range of advanced and certified materials, including:

- Our Repsol Reciclex® range of polyolefins that manages to recover polymers from cars that have reached the end of their useful life, guaranteeing the supply of new homogeneous materials that contain recycled material.

- New very high-impact resistance range of polypropylene grades under the Repsol Impacto® brand.

- Polypropylene compounds for interior and exterior applications designed to meet the most demanding customer requirements.

- High-density polyethylene for fuel tanks.

- A range of polyols to enable its automotive customers to meet their highest requirements and goals both in the field of soundproofing and with the arrival of the electric vehicle, in addition to those related to the seat module, weight reduction and interior comfort.

Safety for everyone

Thanks to our research efforts, we develop the most innovative materials to help enhance vehicle safety.

One example is our high-impact polypropylene copolymers and compound solutions. These materials combine both high impact and high stiffness, making them ideal for use in vehicle interiors as the offer greater passenger safety. Instead of breaking, this ductile material is capable of absorbing impacts. What’s more, this material meets the requirements for low volatile compound emissions.

In this regard, the RepsolTechLab’s Polyolefin Laboratory was verified by the Volkswagen Group in the "Round Robin 2020,” the company’s test for approving labs that evaluates the odors and emissions of interior car parts in accordance with their internal standard VW 50180, before releasing them onto the automobile market. Therefore, air quality inside the car is analyzed. We passed two tests that determine condensable substances and total volatile organic compounds.

Our work also covers many other products polypropylene, used in door panels; high-molecular-weight polyethylene for fuel tanks; EVA copolymers used in adhesives; and industrialpropylene glycol key when it comes to reducing the freezing point of water in cars.

Moreover, given that they boast excellent thermal stability, the parts manufactured with these materials don’t dilate or shrink when exposed to temperature changes. Nor do they emit vibrations or noise, improving comfort along the way.

Working for a more sustainable world

At Repsol, we’re committed to reducing our environmental impact. One of the ways we achieve this is by manufacturing lighter materials which, in turn, help to manufacture lighter vehicles that consume less fuel.

The components found in plastic help make vehicles up to 100 kg lighter, reducing fuel consumption by approximately 0.5 litres for every 100 km and CO2 emissions by 10 g/km.

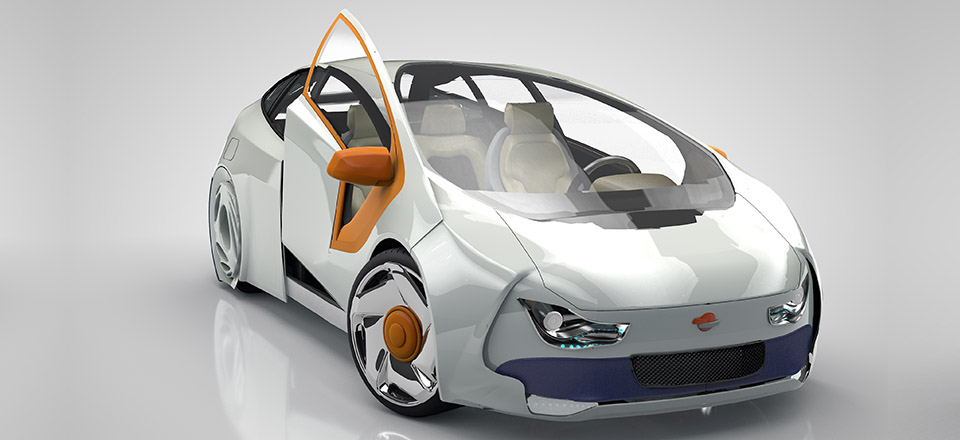

Cars today contain up to 15% plastic materials, which equates to more than 2,000 plastic parts, including those used in headlights, trims, sunroofs, and other security-based applications, like for example:

- Airbags and seatbelts.

- High-impact elements: hatchback doors, door panels, instrument panels, and interior trims.

- Seats and headrests that protect passengers when accidents occur.

- Structural parts under the hood, fuel tank, and cables.

- Fenders and bumpers.

- Paints and coatings.

- Insulation, soundproofing, and antifreeze.

As the automotive industry is a basic part of society, at Repsol we continuously count on our innovation, research, and cutting-edge technology to make sure your journeys are safe, comfortable, and environmentally friendly.