Everything about planned obsolescence

Optimizing resources towards a circular economy

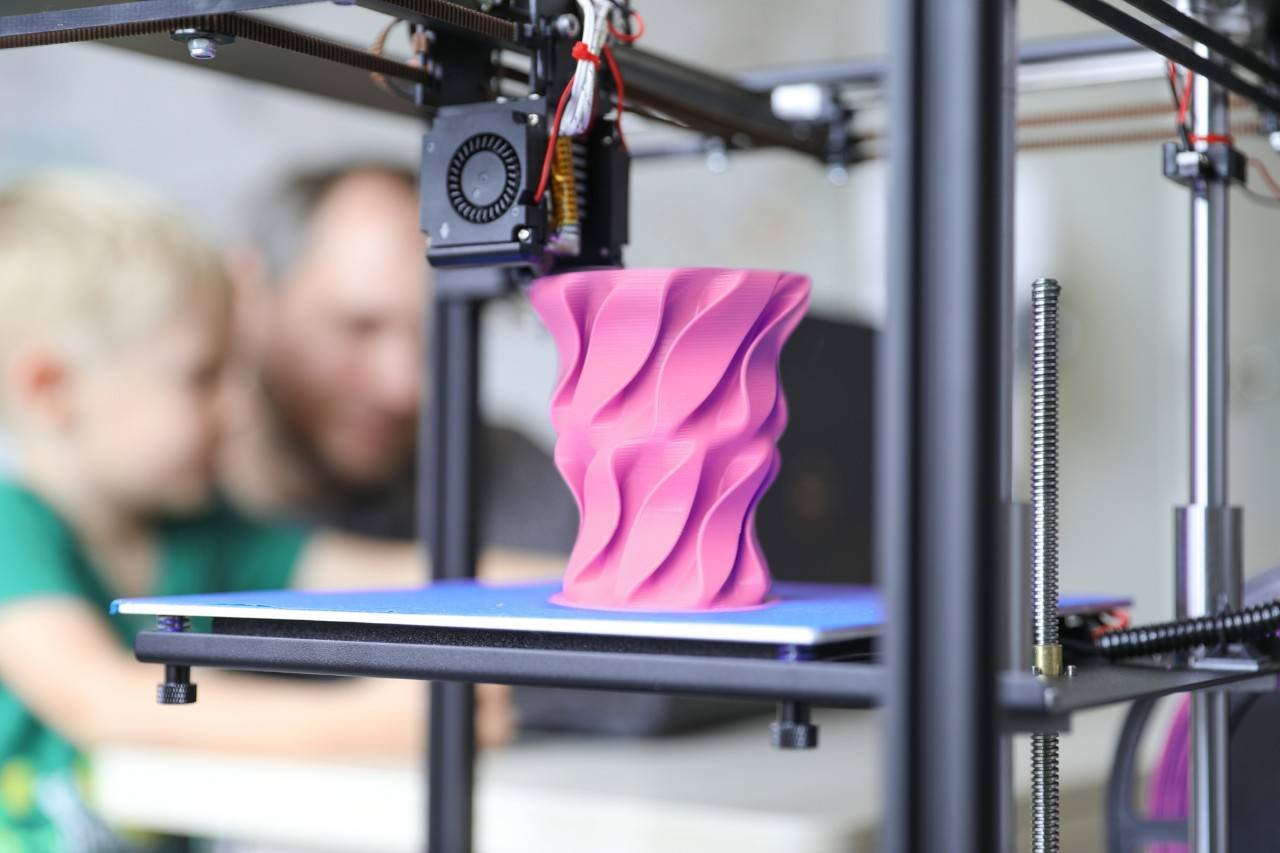

3D printing

A world of possibilities

For the development of prototypes, automotive spare parts, for the manufacturing of industrial parts, or even drugs or prostheses, 3D printing has positioned itself in recent years as a technology with multiple applications in many different fields, faster and cheaper than other processes.

The first 3D printer was manufactured and patented in 1984 by the American physicist Charles W. Hull, cofounder and technology director of the company, 3D Systems. It was based on what Hull called stereolithography: additive printing (in other words, it works by adding different layers in three dimensions) by photo-solidification; in his case, by exposure to ultraviolet light.

In the last few decades, 3D printing has experienced a surge thanks to the many applications and possibilities that they represent for the technology industry. We tell you what it consists of, how 3D printers work, and many of their applications.

What is 3D printing?

3D printing is a technology that allows you to create three-dimensional objects by adding material layer by layer. Its development has represented a revolution in industrial manufacturing and in many other fields, as 3D printers are able to reproduce a three-dimensional model more quickly and easily by means of additive manufacturing, as opposed to traditional methods that required cutting, drilling, or sculpting the material.

From 3D printing designs, these printers convert digital designs into physical objects. 3D printers can use various materials, of different properties, even in the same design, among them polylactic acid, high impact polystyrene, Laywoo-d3, acrylonitrile butadiene styrene, or polyethylene terephthalate, and even metals and resins, all of which have high strength but different physical properties.

3D printers enable faster, simpler, and lower-cost manufacturing than other traditional manufacturing technologies, and are also of great value to product designers and developers, who can create their models and prototypes more easily and economically.

How does 3D printing work?

3D printing starts with a 3D printing design: a digital model in three dimensions that is created by using a computer-aided design (CAD) software, such as Tinkercad, Blender, or AutoCAD. Alternatively, an existing object can be scanned with a 3D scanner to create its digital replica.

Once the digital model is created, it is divided into very thin horizontal layers by a process known as slicing. This process is performed by a specific software called slicer, which translates the 3D printing design into instructions that the 3D printer can follow. The slicer software generates a file in G-code format, which contains the specific instructions for printing the object layer by layer.

The 3D printer deposits the chosen material layer by layer, moving the printhead according to the coordinates of the G-code file and adding the material where it is needed. There are different 3D printing technologies. The most common is Fused Deposition Modeling (FDM), in which a plastic filament is melted and extruded through a heated nozzle. Other technologies include Charles W. Hull's early model stereolithography, which uses a laser to solidify liquid resin, and Selective Laser Sintering (SLS), which uses a laser to synthesize material powder.

Once the printing is completed, the object may require post-processing, which may include the removal of support structures, sanding, polishing, or a painting process to achieve the desired finish. In some technologies, such as SLA printing, the printed object must be further treated with ultraviolet light to achieve its final strength.

Join our team!

Launch your career in big data and help us to create the future of energy.

Applications of 3D printing

In an early stage of development, 3D printing was primarily used for design and prototype development, but nowadays 3D printers are also used for the creation of final products in various areas, from the aeronautics industry to medicine, as well as being used in education or art.

These are some of the applications for which 3D printing is already being used:

As other examples of 3D printing applications, Repsol uses this technology in different projects, such as the production of metal spare parts for its Petronor refinery, ecodesign projects, or the creation, together with the startup Recreus, of a fiberglass filament for use in these printers. It also collaborates with the NGO Ayúdame3D, which has already delivered more than half a thousand prosthetic arms made from recycled plastics in 55 countries, free of charge.