Get to know the chemical recycling of mattresses

Get to know the chemical recycling of mattresses

Chemical recycling of polyurethane foam

Our Repsol Reciclex® polyols range

With this new process, we'll produce circular Repsol Reciclex® polyols, which closes the loop for this kind of waste by giving it a new life.

It's a new recycled polyol that is produced from post-consumer polyurethane foam in mattresses. This polyol can be incorporated into regular processes for new foam production, thus closing the cycle of the circular economy of this material.

Get to know the chemical recycling of mattresses

Expanding our partnerships to produce polyols

We signed an agreement with RAMPF Eco Solutions, a German company expert in chemical solutions for producing alternative high-quality polyols, which grants us exclusivity throughout Europe to develop and build new flexible polyol recycling plants using various sources and qualities of post-consumer polyurethane waste.

This agreement makes it possible for both companies to join forces, our extensive recycling knowledge and experience, as well as our polyol production capacity and engineering. By making the most of these synergies, both of our companies will be able to promote the efficient recycling of flexible foam.

This partnership demonstrates our goal to transform our industrial complexes and turn them into multi-energy hubs capable of producing products with a low, zero, or even negative carbon footprint. This also shows our ambition to close the loop upon recycling these essential products by offering sustainable solutions both for polyurethane converters and end consumers.

The project in figures

2,000

tonnes/yearof external waste processed at our facilities equal to 200,000 mattresses

5,000

tonnes/yearof circular polyols from our Repsol Reciclex® range

€12 M

invested in the plant

2023

Expected start-up year

Circular benefits

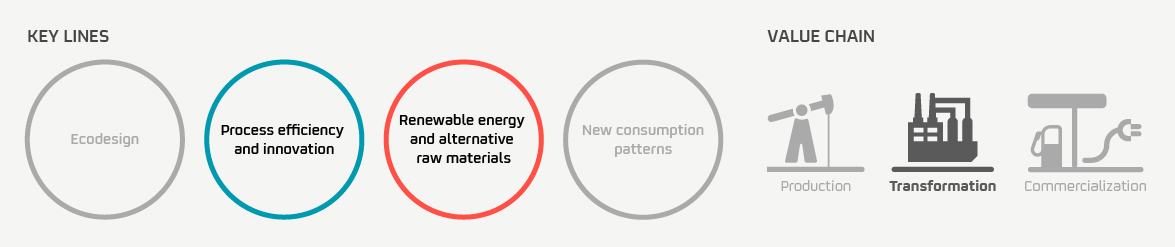

Classification by key lines and value chain

Our circular economy projects are aligned with the key lines of our strategy and are present throughout our entire value chain, from obtaining raw materials to commercializing products and services.

Find out more about our circular economy projects

Find out more